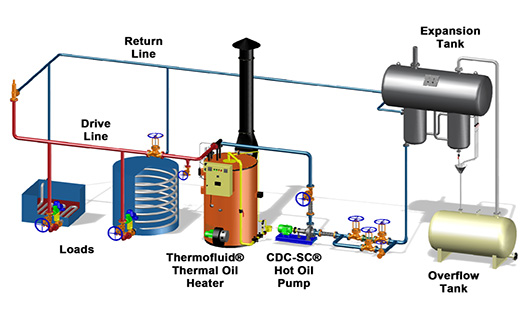

Technological alternative, more suitable, efficient and cost-effective for the indirect heating in industrial processes.

- Working temperature up to 350 °C at very low pressure.

- Specially designed for high transfer speed and a get great power of heat exchange.

- Achieves high temperatures at pressure of recirculation.

- Suitable for the latest technology of synthetic thermal fluids, mineral and food grade.

- The selection of the model of the heater depends on many factors of the process to implement and system that will work. We can advise you fully in the design or modernization of their installation.

Advantages of systems of fluid thermal vs. Steam.

- They can be high temperature (350 ° C – 662 ° F) at very low pressure steam systems that require high pressures of work unlike.

- Boiler operator certificate is not required.

- Saving fuel (up to 20%). Savings in the maintenance of pipelines.

- Does not consume water caused by condensation losses.

- Recovery steam traps are not required.

- The transfer fluid does not need treatments such as water.

- It is not corrosive like steam.

- May be controlled several consumptions at the same time with different temperatures each.

- No risk of freezing.

- Monotubular vertical design of excellent performance.

- Quick entry into the regime. Equipment with multiple securities. Suitable for every type of industry.

- High efficiency modulating burner.

- Natural gas, LPG or diesel burner.

- Electronic temperature PID control.

- Easy process and accuracy control.

- Control of operational temperature +/- 1 °C.

- Vertical construction which occupies less floor area.

- Also you can find it is near the consumptions (punts, reactors, furnaces, etc.), reducing considerably the laying of pipes and, therefore reduces losses of heat on the way.

- Automatic operation without supervision.

- Very low maintenance costs.

Thermofluid® heaters are used in a wide variety of industrial processes namely:

- Adhesives.

- Asphalts.

- Autoclave.

- Bio-diesel.

- Chemical reactors.

- Distillation.

- Food processing (frying, baking, etc.).

- Hot water generation.

- Inks.

- Laundry services.

- Surfaces and finishing treatments.

- Heating in vessels and on board services.

- Metal finishing.

- Mining.

- Ovens.

- Manufacture of paint and varnish.

- Machinery for paper and corrugated board industry.

- Plastics.

- Printing.

- Rubber and rubber compounds.

- Textile machinery.

- Uranium processing.

- Waste recycling.

- Dryers.

- All process requiring heat.

| Tabla de Especificaciones | ||||||

| Thermofluid® Heaters Models |

Neat Heat Capacity 1000 kcal/h | Oil Capacity lts | Gas Oil Consumption lts/ h | Natural Gas Consumption m3/ h | Gas Oil Supply Ø mm | Natural Gas Supply Ø mm |

| TF-70 | 70 | 11 | 8 | 8 | 13 | 25 |

| TF-200 | 200 | 30 | 23 | 24 | 13 | 32 |

| TF-400 | 400 | 71 | 47 | 50 | 13 | 38 |

| TF-600 | 600 | 117 | 70 | 72 | 19 | 50 |

| TF-1000 | 1000 | 286 | 115 | 119 | 19 | 63 |

| TF-1500 | 1500 | 465 | 170 | 182 | 25 | 63 |

| TF-2000 | 2000 | 630 | 230 | 246 | 25 | 76 |

| TF-2500 | 2500 | 1102 | 285 | 307 | 25 | 76 |

| TF-3000 | 3000 | 1390 | 340 | 390 | 25 | 76 |

| Overal Dimensions | ||||||

| Thermofluid® Heaters Models | Net Heat Capacity 1000 kcal/h | A mm. | ØB mm. | C mm. | D mm. | Weight kg. |

| TF-70 | 70 | 1120 | 465 | 600 | 250 x 100 | 220 |

| TF-200 | 200 | 1550 | 645 | 980 | 300 x 200 | 375 |

| TF-400 | 400 | 1940 | 890 | 1310 | 350 x 250 | 800 |

| TF-600 | 600 | 1960 | 1066 | 1490 | 400 x 300 | 1200 |

| TF-1000 | 1000 | 2490 | 1250 | 1725 | 450 x 350 | 2000 |

| TF-1500 | 1500 | 3300 | 1450 | 1980 | 550 x 450 | 2660 |

| TF-2000 | 2000 | 3300 | 1790 | 2390 | 600 x 500 | 3800 |

| TF-2500 | 2500 | 3290 | 2280 | 3370 | 600 x 500 | 4800 |

| TF-3000 | 3000 | 3290 | 2740 | 3850 | 700 x 550 | 6000 |