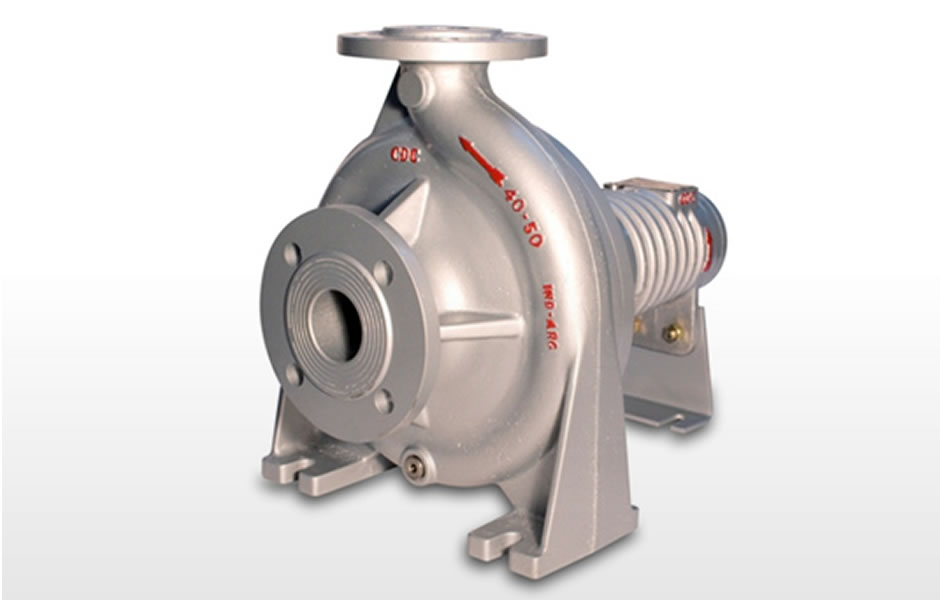

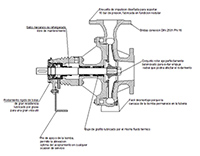

The line of CDC®SC Pumps for thermal fluid is developed under “Back Pull-Out”. This system allows the fullrotating parts disassembly by the attachment side, leaving snail attached to the base and the pipes of suction and discharge, without uncoupling the same.

Therefore, repair times and costs of labor are drastically reduced allowing the fast back to process line operation.

CDC®SC Pumps for the handling of mineral or synthetic thermal fluids are designed to work at temperatures up to 350 °C (662°F). Manufactured entirely in nodular cast iron of high resistance and designed according to standards, to support up to 18 bar of pressure.Their Rotor-Shaft assembly is perfectly balanced, to avoid radial forces that could affect the bearing, thus increasing their useful life.

Designed with one single ball bearing and graphite bushing, provides optimum reliability to the set. Provided with Mechanical Seal (Mechanical Seal according with EN 12756), responds the last state of the art. The pumps can be installed with positive or negative suction pressure. Spare parts are guaranteed as technical service.

- Maximum flow: 300 m3 / h. (1300 gal/min).

- Maximum Height Gage 90 m.(295 ft).

- Maximum Spin Speed: 3600 rpm.

- Maximum working temperature: 350° C.(660ºF).

- Flange connection DIN 2501 PN 16.

- Rotation: Clockwise (seen from the top of the drive shaft).

- 16 bar, at 0°C-120°C. (32ºF- 248ºF).

- 13 bar, at 120°C-300°C. (248ºF- 572ºF).

- 10 bar, at 300°C-350°C. (572ºF- 662ºF).

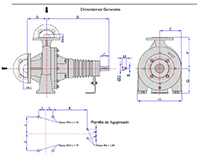

| Pump dimensions (mm) | |||||||||||||||

| Model CDC | DNE | DNS | A | B | C | ØD | E | F | G | H | I | J | K | L | M |

| 20/25 | 25 | 20 | 80 | 285 | 51 | 24 | 110 | 158 | 130 | 220 | 27 | 75 | 119 | 25 | 28 |

| 25/25 | 25 | 25 | 95 | 300 | 51 | 24 | 115 | 163 | 135 | 230 | 30 | 88 | 126 | 25 | 28 |

| 32/50 | 50 | 40 | 108 | 318 | 50 | 24 | 123 | 175 | 140 | 250 | 40 | 95 | 195 | 25 | 28 |

| 40/50 | 50 | 40 | 108.5 | 321 | 50 | 28 | 139 | 199 | 159 | 284 | 50 | 110 | 146.5 | 40 | 32 |

| 40/65 | 65 | 40 | 110 | 325 | 50 | 28 | 175 | 222,5 | 185 | 320 | 50 | 127.5 | 170 | 40 | 32 |

| 50/65 | 65 | 50 | 115 | 390.5 | 50 | 28 | 130 | 190 | 160 | 270 | 52.5 | 95 | 165 | 40 | 32 |

| 60/80 | 80 | 65 | 106 | 343,5 | 50 | 28 | 157.5 | 231 | 180 | 345 | 52 | 133 | 170 | 40 | 32 |

| 80/100 | 100 | 80 | 125 | 391 | 50 | 28 | 181 | 253 | 194 | 328 | 53 | 126 | 213 | 40 | 32 |

| 100/125 | 125 | 100 | 157 | 397.5 | 50 | 28 | 198 | 250 | 200 | 370 | 54 | 145 | 213 | 40 | 32 |